Technology Myrtha

TECHNOLOGY

Myrtha technology is the most advanced in the field of swimming pool construction. Whether it is a competition swimming pool for the Olympic Games or a leisure pool, Myrtha technology has the solution.

It is a patented prefabricated technology. The factory, PVC-coated, stainless steel panels, combined with a resilience system ensure, in addition to absolute watertightness, strength and stability.

With its technical characteristics and its construction flexibility, it overcomes the obstacles encountered by conventional constructions and simple prefabrication.

The use of high stainless steel ensures long lifespan even in places with high water table or near the sea. All parts of the structure are connected together with screws and at no point is electro-welding used that could cause oxidation.

The PVC membrane used for the waterproofing, is a material that is soft to the touch but at the same time non-slip. It has been properly treated against solar radiation and the build-up of micro-organisms.

ADVANTAGES

This technologically advanced way of construction, through continuous study and development, has particular advantages over other ways of construction:

1

The swimming pool can have any shape and dimensions.

2

All stages, from production to installation, are controlled by the manufacturer and local specialized dealers.

3

Installation is very short and possible errors are eliminated, as it is an industrialized product ( ISO 9001).

4

The initial investment cost is predetermined, with no contingencies and maintenance costs are minimal over time.

5

Long life span.

6

Unlike conventional construction methods, Myrtha does not require particular maintenance. It will not crack, deform or be affected by water and its chemicals.

7

It has micrometric production and installation mechanisms, fully meeting international requirements for high-level competitions.

8

It has a wide variety in the way of construction, in terms of the aesthetic “finish” of the construction.

9

Can be installed in any place (in-ground, above ground, unstable soils, building floors, etc.).

10

It is considered a “green” technology as its energy footprint is 50% less than conventional concrete and tile construction.

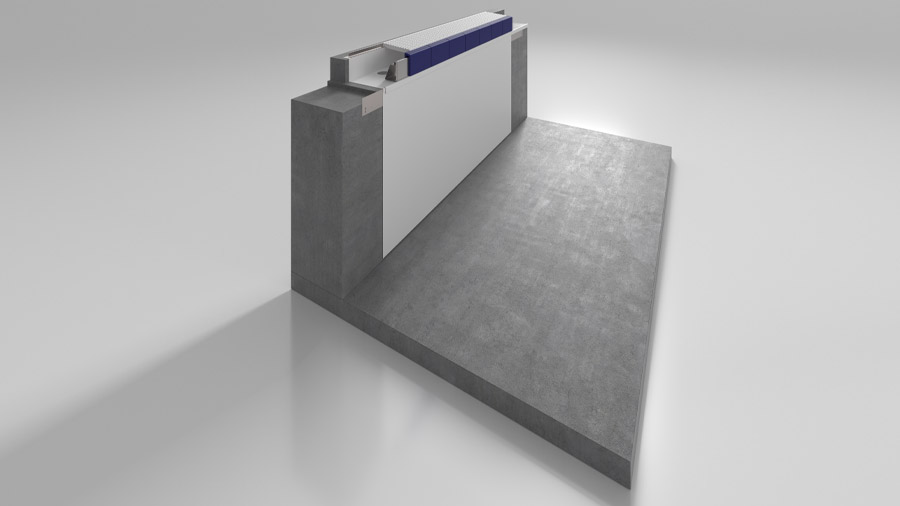

ANODIZED-STAINLESS CONSTRUCTION

The Myrtha Pools system starts with stainless steel. Our chromium-rich alloy offers both the strength and chemical and corrosion resistance required in a pool environment. To ensure long lifespan, structural components such as clamps, guides, panels and ducts are securely bolted together – not welded, as steel welding can leave the frame susceptible to corrosion.

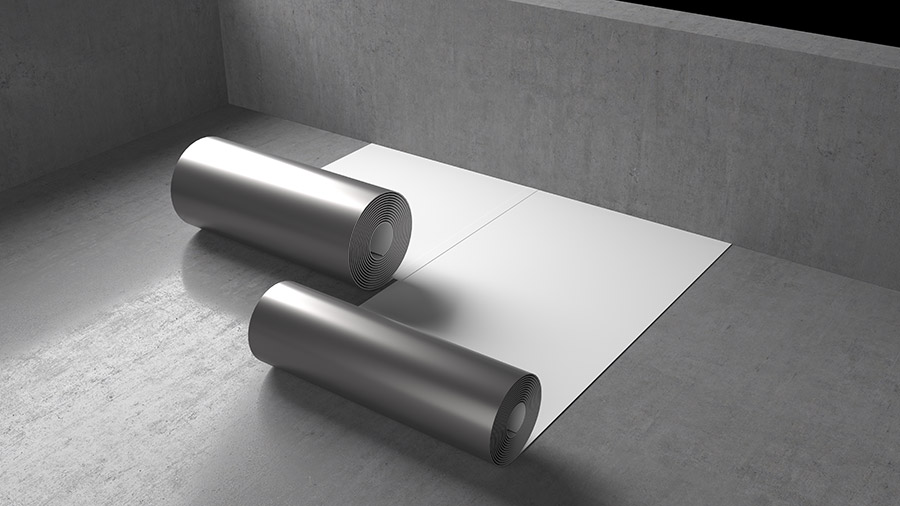

PVC WATERPROOFING

Offering durability and highly effective waterproofing, our stainless steel panels are hot rolled with multilayer PVC. All joints, the floor surface and spaces between wall panels are sealed to create a tight, waterproof tank.

FINISHES

The many finishes available for Myrtha Pools offer both functional and aesthetic benefits. Thanks to our robust laminated PVC, almost all finishes of tile, glass and stone suitable for pool environments can be used to customize the pool design. For a “wow” factor, our acrylic wall panels, which are similar to glass in appearance but much more suitable for pool environments, more transparent and lighter, create a stunning finish.

MYRTHA SKIN FOR THE POOL FLOOR

Myrtha Skin is the new technological solution developed by Myrtha Pools for the waterproofing of swimming pool floors. Combined with Myrtha’s modular panel technology, the “Skin” makes it possible to create a 100% steel pool that provides all the advantages that Myrtha’s exclusive modular technology already offers to architects, designers and owners. Myrtha Skin is only 1mm thick and flexible enough to be dispensed in coils and uses the same steel and PVC fusion that is the basis of Myrtha panels. The results of studies carried out by the Research and Development Centre confirm that Myrtha Skin guarantees perfect waterproofing combined with unique underwater visibility for a 100% steel pool and superior overall performance.

MYRTHA SKIN FOR POOL WALLS

Ideal for swimming pool flooring, Myrtha Skin can also be used to renovate pool walls. Split into flexible coils and only 1mm thick, Myrtha Skin uses the same basic system used in our steel and PVC panels. The result of the studies carried out by our R&D team reveals that Myrtha Skin represents a more flexible solution during the construction phase, while guaranteeing superior strength and overall performance.

CONSTRUCTION PARTS

All parts of the metal construction are made of stainless steel. Each structural element is properly designed and manufactured with absolute precision, so that after completion of assembly, they all come together to form a single and rigid structure. Only the bottom of the swimming pool is made of a thin slab of concrete which forms the support base of the metal structure.

The parts that make up the structure are :

The Base

The Base

The baffles

The baffles

The struts

The struts

The overflow gutter

The overflow gutter

The above parts, combined with the special applications for the sealing of the metal structure, the bottom membrane and the special accessories complete a swimming tank of high standards and reliability.